- Home

- Showers

- Tempering Valves

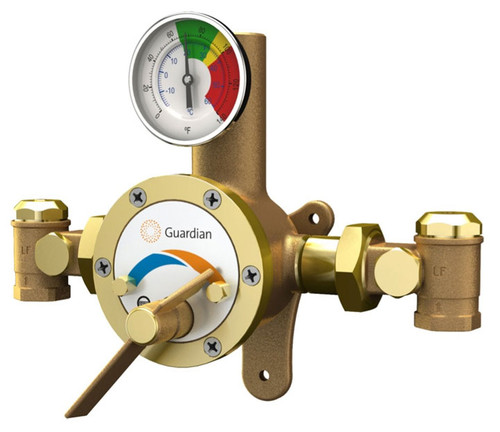

- Guardian G3800LF Tempering Valve, 44 Gallon Capacity

Product Description

APPLICATION NOTE: This valve was discontinued in September of 2021. Repair parts are no longer available. The recommended replacement is the G6040 tempering valve.

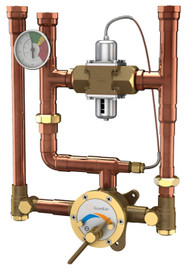

The G3800LF is suitable for use with a single installation of emergency showers and safety stations, and with multiple installations of emergency shower, eyewash, eye/face wash, dual purpose eyewash/drench hose, drench hose and safety station units. The G3800LF valve is available in two additional configurations. The G3802LF is the same valve but installed in a surface-mounted stainless steel cabinet. The G3807LF is installed in a recess-mounted stainless steel cabinet.

We carry a full line of tempering valves ranging in capacities from 6 to 81 gallons per minute (GPM). The valve must be properly matched to the flow capacity of the safety station in order to deliver water within the tepid range.

Application: Tempering valve to blend hot and cold water to deliver tepid water. Valve has flow capacity of 3.0 to 44 gallons per minute (GPM). Valve can be used with a single installation of emergency showers and safety stations, and with multiple installations of emergency shower, eyewash, eye/face wash, dual purpose eyewash/drench hose, drench hose and safety station units.

Temperature Control: Valve has bimetallic thermostat that senses incoming water temperature and automatically blends water to 85 °F (29 °C). High temperature limit stop is set to 90 °F (32 °C). Valve has dial thermometer on outlet to monitor temperature of delivered water. Note: Valve may need to be adjusted when installed based on incoming water temperature. Refer to “Installation Instructions” for further information.

Fail Safe: In event of restriction or failure of hot water supply, internal bypass allows valve to deliver cold water to emergency unit. In bypass mode, valve will deliver 20 GPM of cold water at 30 PSI flow pressure. In event of loss of cold water supply, valve will close and not deliver water.

Flow Capacity: Refer to chart below for flow capacity of valve at specified pressure drops:

| System Pressure Drop (psi) | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

| Flow rate (gallons per minute) | 20 | 25 | 30 | 33 | 35 | 38 | 43 | 50 |

| System Pressure Drop (bar) | 0.3 | 0.7 | 1.0 | 1.4 | 1.7 | 2.1 | 2.4 | 2.8 |

| Flow rate (liters per minute) | 76 | 95 | 114 | 125 | 132 | 144 | 163 | 189 |

Supply Temperature: Minimum hot water supply temperature is 140 °F (60 °C).

Supply Pressure: 30 PSI minimum supply pressure is required for proper operation of valve. Maximum supply pressure is 125 PSI. Maximum hot to cold water pressure differential is 5%.

Mounting: Furnished with heavy duty mounting bracket for securing valve to panel or wall.

Inlets: 1" NPT female hot and cold water inlets. Inlets can be rotated 360 degrees for top or bottom supply. Each inlet has integral water strainer, check valve and supply stop.

Outlet: 1-1/4" NPT female outlet.

Quality Assurance: Valve is completely assembled and water tested prior to shipment. Valve is certified to ASSE 1071. Valve is certified to meet low lead requirements of wetted surface area less than 0.25% lead by weight.

Application Note: Pursuant to ANSI Z358.1-2014, the water delivered by emergency equipment should be "tepid". Tepid is defined as moderately warm or lukewarm, and is generally considered to be between 60 °F (15 °C) and 90 °F (32 °C). However, in certain circumstances, a chemical reaction may be accelerated or otherwise affected by the water temperature. Please consult with a medical advisor to determine the optimum delivered water temperature prior to specifying, installing or using a tempering valve.

Tempering valves will not deliver the appropriate water temperature if the system has not been sized correctly. Please refer to the flow capacities and supply pressure requirements listed above when designing the tempered water system and selecting tempering valves.

Tempering valves, like all emergency eyewash and shower equipment, must be installed in accordance with the manufacturer’s instructions and maintained on a regular basis. Under ANSI Z358.1-2014, all emergency equipment should be activated weekly and inspected at least annually. Tempering valves should be treated the same and, in addition, must be regularly cleaned and cycled.

Documentation available: G3800LF specification sheet w/ measured drawings, installation, operation and maintenance guide, and written specifications (Word format).

Common replacement parts: With proper weekly cycling these valves should give you years of trouble-free service. If you encounter an issue, contact Guardian Technical Support to troubleshoot. If the factory identifies an component issue, we can special order any parts you may require.

Shipping weight - 17 lb (7.7 kg).

Warranty Information

2-year manufacturer limited warranty.

Loading... Please wait...

Loading... Please wait...